Measurement Devices for Your Mechanical Industry

In any mechanical industry, gauging devices are very vital. These devices are used to check the flow measurement as well as the energy value in the industry. There are many water flow measurement devices available in the market. But, picking the right tool is never a walk in the park. Below are some devices used in the mechanical industry. Ensure you follow this guide to the latter to get to know about those devices.

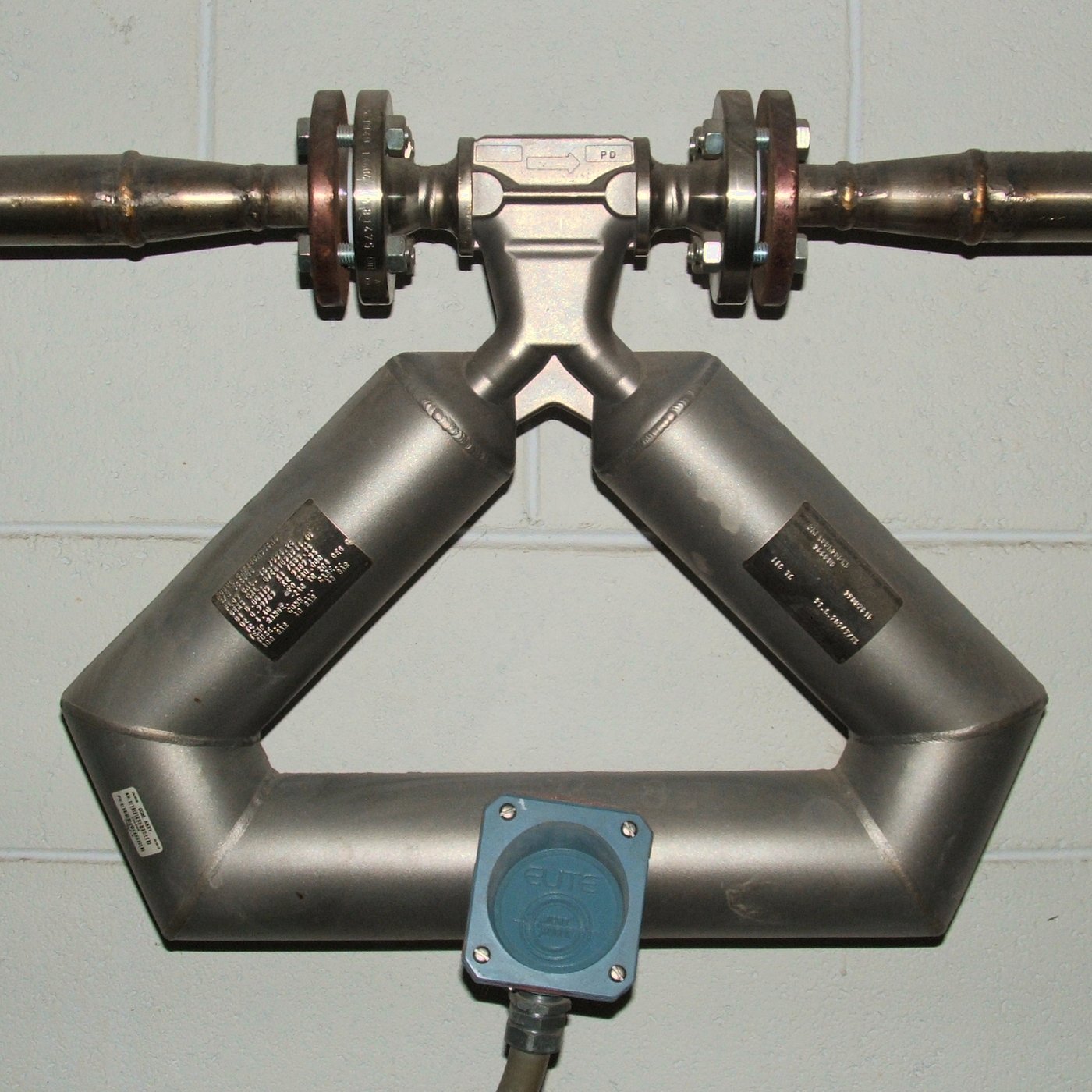

Mass Flow Meter

The mass sensors are of the most used flow measurement devices. They gauge the volumetric flow and the density of the liquid through some elements.

Coriolis meters gauge the flow of liquids while the thermal mass sensors estimate the flow of gasses. Various types of impact flow meters estimate the flow of solids. The Coriolis mass sensors match the mass flow to the fluid's inertia sensed if it is incited by shaking within the sensor tubes. These types of mass meters are ideal for custody shift gauging of fluids.

When it comes to thermal sensors, they fit the mass flow to the energy's quantity shifted from the heated prod to the moving fluid. Some of the designs used for gauging the bulk solids are:

- The Radiometric nuclear source: These devices match the mass flow to the quantity of emission soaked up by a receiver fitted opposite the nuclear source.

- Impact Plate and Deflection Chute: The devices correlate the mass flow of dropping bulk loads to the receptive energy put to an impact plate. The impact plate and deflection chute use the installed load cells to gauge the flow.

- Weigh belt: The weight belt is also termed as the feeder. It uses the mixture of the continuous gauging system load cells and the velocity sensing of the feeder or belt to know the flow rate of mass.

- Coriolis Mass Meters: These devices fit the mass flow to the twist gauged by a load cell on a dynamic gear, spinning constantly. That occurs when the particles are moving onto a region that is offset from the hub.

Differential Pressure Meters

Gulf force meters match the flow to the gauged force gulf across the inline sensitizing particles. The elements include:

- Venturi tube

- Flow nozzle

- V-cone tube

- Pitot tube

- Variable are sensor

- Annubar sensor

- Averaging Pitot tube

- Wedge flow elements

- Orifice plates

- Rotameter

Gulf force transmitters have low and high force ports linked to a valve manifold. That enables the impulse tubing to be connected to any of the flow sensing articles. The valve manifolds come in five-valve and three-valve layouts. They are ideal for many uses, giving a perfect low-cost solution for linking wires to their bent tubing.

The layouts found in the three-valve gives span and nix calibration. They also have extra ports to link the test tools. The five-valve design provides the extra ports for draining or purging of the goad tubing.

The bent tubing size is usually half an inch, and most times, there is heat traced when the liquid freezes in them. In cases where the process liquid requires being separated from the main meter because of rusting or extreme heat, the gulf force wires with goad tubing and valve manifolds are replaced by gulf hose wires with capillary tubing and diaphragms.

Typically the process is linked by the diaphragm seals. The transmitter, capillary tubing, and diaphragm seals have a fill fluid. That is the type in which the application is reliant.

You can get many fill fluids in the market you can pick from, listed in the dealer's specs. The food-grade fill fluids are ideal for food sectors while the other fill fluids are applied in chemical firms or sectors.

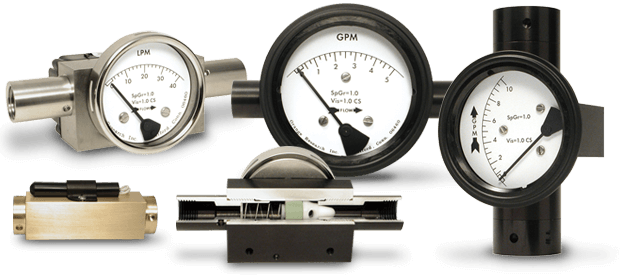

Velocity Meters

The velocity meters fit the flow to the gauged flow speed and the other parts of the sensors. Such parts are:

- Turbine Meters: Turbine sensors fit the flow to the internal gears or turbines. It is ideal for custody shift gauging of fluids.

- Magnetic Sensors: These tools match the flow to the voltage gauged when induced by fluid flowing across a magnetic field.

- Vortex Flow Meters: Vortex sensors correlate the fluid flow to the reliability of the vortices produced in the flow element. These tools are ideal for clean liquids, steam, and pure vapors gauging.

- Swirl meters: The swirl meters have a swirl particle at the inlet and de-swirl particles on the outlet.

- Transit Time Ultrasonic meter: Transit time ultrasonic meter correlates the flow to ultrasound shown from the wire. Yet the ultrasound has to insert and reflect for the meters to work.

Final Word

As you have noticed, there are many flow measurement devices. They come in varied designs and uses. You need to be careful when choosing your next water flow measurement device for your mechanical firm. That will help you cut some repair expenses as well as help you to work under your budget.

- Comment

- Posted by Naman Modi