Creating Bispecific Antibodies: Giving No Chance to Chance

Discover the complexities of bispecific antibodies (bsAbs), their production challenges, and purification strategies that enhance therapeutic efficacy in cancer, autoimmune, and infectious disease treatments.

The development of bispecific antibodies (bsAbs) has allowed groundbreaking advancement in the field of therapeutic antibodies, offering new solutions for diseases that have been difficult to target with traditional monoclonal antibodies.

However, the process of generating bsAbs is complex and fraught with challenges, where chance sometimes takes on a larger part than reasonable… and necessary. This is mainly the case in the actual manufacturing of bsAbs, as assembling their individual components needs more than a guiding hand to supervise the process, including specialized approaches to ensure high yields of bsAbs of sufficient quality. But the challenges neither begin nor end at the assembly of bispecific antibody molecules, as the individualization of the most appropriate bsAb candidate may be just as tricky as antibody purification towards the end of a production run.

The following sections will provide a more detailed insight into these three aspects—antibody selection, production, and purification—that set bsAbs apart from other antibody products. Furthermore, approaches will be discussed for each of these fields in order to ensure that there is as little room for deviation as possible.

Where bispecific antibodies play out their double-strengths

Bispecific antibodies are cutting-edge therapeutic molecules engineered to bind two different targets simultaneously (or two different epitopes on the same target). This allows them to operate through various mechanisms, enhancing their therapeutic potential.

One of the primary mechanisms of bsAbs is T-cell engagement, where they bridge T-cells and cancer cells, enabling the immune cells to directly target and kill tumor cells. By binding to a T-cell antigen on one side and a tumor-associated antigen on the other, bsAbs facilitate a potent immune response against cancer.[1]

In addition to T-cell engagement, bsAbs can inhibit multiple signaling pathways involved in disease progression. For example, in cancer therapy, they can block different growth factor receptors on tumor cells, effectively shutting down pathways that the tumor relies on for growth and survival.[2]

BsAbs can also cross-link two different receptors on the same cell, triggering or inhibiting specific cellular responses. This approach is valuable in modulating immune cell activity or preventing signaling pathways that contribute to disease.[3] Moreover, bsAbs can be designed for targeted therapeutic delivery, binding to specific cell surface targets and facilitating the internalization of therapeutic agents. This mechanism is particularly useful in the development of antibody-drug conjugates (ADCs), where bsAbs deliver cytotoxic drugs directly to cancer cells, minimizing damage to healthy tissue.[4]

Accordingly, the therapeutic applications of bsAbs are vast. In oncology, they have shown significant promise by recruiting immune cells to tumor sites, blocking multiple cancer growth signals, and delivering cytotoxic agents directly to cancer cells. This enhances the efficacy of cancer immunotherapy, making bsAbs valuable in treating both hematologic malignancies and—increasingly—solid tumors.[5]

In autoimmune diseases, bsAbs can inhibit multiple pro-inflammatory cytokines, or inhibit T- or B-cell proliferation/activation, providing a versatile approach to reducing inflammation and modulating the immune response.[6]

BsAbs are also emerging as powerful tools in combating infectious diseases. Their T-cell-engaging mechanism enhances the immune system's ability to fight infectious agents.[7] Furthermore, bsAbs hold potential in treating neurological disorders by crossing the blood-brain barrier and targeting specific neurological targets, offering new hope for conditions like Alzheimer's disease and other neurodegenerative disorders.[8]

But to exploit all of these benefits, researchers and pharmaceutical companies need to obtain the specific bsAbs that meet their exacting standards. Challenges in that regard commence in the development process.

First things first: What bispecific antibody should you go for?

Selecting the right bsAb involves considering the disease target, desired mechanism of action, and therapeutic goals. The process begins by identifying the disease and relevant biological pathways. For oncology, targeting tumor-associated antigens and engaging immune cells, like T-cells, is key. In autoimmune diseases, inhibiting pro-inflammatory cytokines may be the focus.

Choosing the optimal bsAb format, such as BiTE® molecules,[9] is as crucial as making engineering considerations, such as enhancing antibody-dependent cellular cytotoxicity (ADCC) or silencing Fc receptor interactions. Technologies like GlymaxX®[10] and STR modification,[11] for instance, can modify Fc activities to suit therapeutic needs.

Practical aspects, including production feasibility and scalability, are also important. Simpler bsAb designs may ease production, while complex formats might offer enhanced functionality but require advanced manufacturing techniques.

Struggles in bispecific antibody production: HCLC pairing as a major challenge

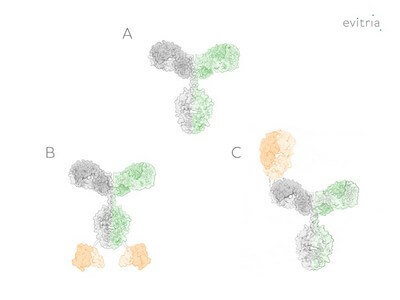

One of the most significant challenges in the production of bsAbs is ensuring the correct pairing of heavy and light chains (HCLC pairing). This process is critical for the functionality and efficacy of bsAbs, but it is fraught with difficulties due to the complex nature of these molecules. In bsAbs, there are two different heavy chains and two different light chains that need to pair correctly, unlike in traditional monoclonal antibodies where the chains are identical and pairing is straightforward.

Mispairing of these chains can result in various unwanted by-products, including homodimers, which are composed of identical heavy chains, and mismatched heavy-light chain pairs. These incorrect pairings not only reduce the overall yield of correctly formed bsAbs, but also complicate the purification process. The production process must, therefore, often contend with a significant amount of product-related impurities.

Achieving the correct HCLC pairing requires optimization of the expression and assembly conditions. Even slight deviations can lead to an unreasonable amount of incorrect pairings, lowering the purity and yield of the final bsAb product.

Separating wheat from chaff: Why bispecific antibody purification is so delicate

Purifying bsAbs is a delicate and challenging process due to their fragility. The primary goal of the purification process is to isolate the correctly formed bsAbs from a mixture that includes homodimers, mispaired chains, and other product-related impurities.

One of the main difficulties in bsAb purification arises from the need to distinguish between correctly assembled bsAbs and numerous by-products that can have very similar physical and chemical properties. These impurities include homodimers, which are antibodies formed from two identical heavy chains, and half-antibodies, which are incomplete antibody fragments. Aggregates, another common impurity, can also form due to the high concentration of proteins and the complex assembly process.

Traditional purification techniques, such as Protein A chromatography, are often insufficient for bsAbs because they may not effectively separate the correctly paired bsAbs from the impurities. This necessitates the use of multiple, highly specific purification steps.[12]

After all, the precision required in bsAb purification is crucial not only for the efficacy of the therapeutic product but also for its safety. Impurities can lead to adverse immune responses or reduce the therapeutic effectiveness of the bsAbs. Therefore, the purification process must be finely tuned to ensure that only the correctly assembled bsAbs are isolated in their pure form.

Given the challenges encountered during bsAb design and production, what can be done to overcome them? As for antibody selection, it is often advised to rely on expertise from different angles, as will become clear in the next section.

Interdisciplinary trials to individualize the ideal candidate

Developing bsAbs requires a multidisciplinary approach to tailor the ideal therapeutic candidate to specific medical needs. This process often involves collaboration between various fields, including molecular biology, protein engineering, and analytical chemistry.

Initially, the focus is on identifying potential candidates through advanced molecular design and engineering techniques. Researchers leverage their expertise in protein structure and function to create bsAbs that can effectively target specific disease pathways. This stage often involves creating multiple antibody formats to compare their performance and stability.

Following the design phase, rigorous testing is conducted to evaluate the efficacy and safety of the bsAbs. This involves analytical techniques to assess binding affinity, specificity, and overall stability. Additionally, functional assays are performed to measure the biological activity of the bsAbs in relevant disease models.

Throughout the development process, continuous feedback from interdisciplinary teams helps refine the candidates. For example, bioinformaticians might analyze data to predict potential issues with immunogenicity or off-target effects, while biochemists focus on optimizing production and purification methods to enhance yield and purity.

Novel pairing strategies emerging for HCLC pairing

Ensuring correct HCLC pairing is a critical challenge in the production of bsAbs. However, recent advancements have led to the development of novel strategies to address this issue, enhancing the efficiency and accuracy of bsAb assembly.

One prominent and already well-established strategy is the "knobs-into-holes" (KiH) design, which promotes the correct pairing of heavy chains by introducing complementary mutations. This approach generates a protrusion on one heavy chain and a corresponding cavity on the other, facilitating the formation of heterodimers while preventing the assembly of homodimers.[12]

Another feasible method is electrostatic steering, which leverages charge differences between the heavy chains to encourage proper pairing. By mutating amino acids to create a positive charge on one heavy chain and a negative charge on the other, this strategy enhances the likelihood of correct heavy chain interactions.[12]

The CrossMab technique addresses light chain mispairing by swapping domains between the heavy and light chains to ensure that only the correct pairs assemble, thereby reducing the occurrence of mismatched chains.[13] Additionally, strategies such as bYlok® bispecific pairing technology focus on the structural modification of antibody regions to facilitate correct heavy and light chain interactions. This technique involves adjusting the position of a disulfide bond to favor correct HCLC pairings, thereby increasing the efficiency of bsAb assembly and resulting in levels of correctly assembled bsAbs higher than 95%.[14] Notably, bYlok® technology maintains natural antibody structure, ensuring stability and minimized immunogenicity. It is also compatible with various expression systems and downstream processing steps, making it a valuable tool in streamlining production processes.

Overview: Promising purification strategies for bispecific antibodies

As already mentioned, purifying bsAbs poses challenges due to their complex structure and the presence of various impurities such as homodimers, mispaired chains, and aggregates. Effective purification strategies are crucial to ensure the quality and functionality of the final therapeutic product.

One of the primary purification techniques used is affinity chromatography, specifically Protein A chromatography. This method exploits the binding affinity between Protein A and the Fc region of antibodies, allowing for the capture of bsAbs. However, due to the presence of impurities that may also bind to Protein A, additional steps are often required.[12]

Ion exchange chromatography (IEX) is another popular technique that separates molecules based on their charge differences. By using a gradient of pH or salt concentration, IEX can effectively distinguish between correctly formed bsAbs and various by-products, including homodimers and aggregates. This method is particularly useful for its high resolution and capacity.

Hydrophobic interaction chromatography (HIC) is employed to separate proteins based on their hydrophobicity—e.g. flow-through mode Capto Butyl ImpRes following protein A purification. These techniques are beneficial for removing aggregates and other hydrophobic impurities from bsAb preparations. By carefully controlling the salt concentration and hydrophobic interactions, HIC can achieve high purity levels.

Multimodal chromatography combines different separation principles, such as ion exchange and hydrophobic interactions, within a single chromatographic step. This approach enhances the resolution and efficiency of bsAb purification, enabling the removal of a broader range of impurities in one step. Techniques like Capto MMC ImpRes have been successfully used to remove multiple challenging impurities in bsAb purification.[15]

Lastly, hydroxyapatite chromatography, a form of mixed-mode absorption techniques, uses both phosphate and calcium interactions to separate proteins. This method is effective in removing both low and high molecular weight impurities, ensuring that the final bsAb product is of high purity and functionality.

Optimizing bispecific antibody production: How to maximize process reliability

Optimizing bsAb production involves advanced design and precise pairing strategies. After the most promising antibody candidate has been individualized, techniques like "knobs-into-holes," electrostatic steering, and domain swapping enhance assembly efficiency, reducing undesired by-products and increasing yields. Purification is equally critical, employing methods such as Protein A chromatography, ion exchange chromatography, hydrophobic interaction chromatography, multimodal chromatography, and hydroxyapatite chromatography.

Given the complexities, many researchers turn to specialized providers of tailor-made bispecific antibody expression services. These experts offer advanced technologies and extensive experience, facilitating faster, cost-effective, and high-quality bsAb production.

Be it with in-house resources or with the help of strategic partners, by leveraging these strategies and collaborations, researchers can produce innovative, high-quality bsAbs that are required for superior therapeutic development and enhanced clinical success, with chance only playing—if anything—a modest part.

Reference(s)

- Schofield D.. Applications of bispecific antibodies in therapeutics. evitria. July 5, 2024. Accessed September 12, 2024. https://www.evitria.com/journal/bispecific-antibodies/applications-of-bispecific-antibodies-in-therapeutics/.

- Lu D, Zhang H, Ludwig D, et al.. Simultaneous Blockade of Both the Epidermal Growth Factor Receptor and the Insulin-like Growth Factor Receptor Signaling Pathways in Cancer Cells with a Fully Human Recombinant Bispecific Antibody. Journal of Biological Chemistry. 2004; 279(4):2856-2865. doi:10.1074/jbc.m310132200

- Li JY, Perry SR, Muniz-Medina V, et al.. A biparatopic HER2-Targeting Antibody-Drug conjugate induces tumor regression in primary models refractory to or ineligible for HER2-Targeted therapy. Cancer Cell. 2016; 29(1):117-129. doi:10.1016/j.ccell.2015.12.008

- Lee NK, Su Y, Bidlingmaier S, Liu B.. Manipulation of Cell-Type selective antibody internalization by a Guide-Effector bispecific design. Molecular Cancer Therapeutics. 2019; 18(6):1092-1103. doi:10.1158/1535-7163.mct-18-1313

- Suurs FV, Hooge MNLD, De Vries EGE, De Groot DJA.. A review of bispecific antibodies and antibody constructs in oncology and clinical challenges. Pharmacology & Therapeutics. 2019; 201:103-119. doi:10.1016/j.pharmthera.2019.04.006

- Zhao Q.. Bispecific antibodies for autoimmune and inflammatory diseases: clinical progress to date. BioDrugs. 2020; 34(2):111-119. doi:10.1007/s40259-019-00400-2

- Sloan DD, Lam CYK, Irrinki A, et al.. Targeting HIV Reservoir in Infected CD4 T Cells by Dual-Affinity Re-targeting Molecules (DARTs) that Bind HIV Envelope and Recruit Cytotoxic T Cells. PLoS Pathogens. 2015; 11(11):e1005233. doi:10.1371/journal.ppat.1005233

- Yu YJ, Atwal JK, Zhang Y, et al.. Therapeutic bispecific antibodies cross the blood-brain barrier in nonhuman primates. Science Translational Medicine. 2014; 6(261). doi:10.1126/scitranslmed.3009835

- Amgen.. BiTE Molecule. Amgen. Accessed September 12, 2024. https://www.amgen.com/stories/2018/08/the-shape-of-drugs-to-come/bite-molecule.

- ProBioGen AG.. GlymaxX®: A Smart Way of Modulating Antibody-Dependent Cell-Mediated Cytotoxicity (ADCC). ProBioGen AG. Accessed September 12, 2024. https://www.probiogen.de/genetic-glyco-engineering-adcc-glymaxx.html.

- Schofield D.. True Fc Silencing Technology: STR from mAbsolve. evitria. March 14, 2022. Accessed September 12, 2024. https://www.evitria.com/journal/recombinant-antibodies/true-fc-silencing-technology-str-mabsolve/.

- Schmidt, S.. Design Principles and Solutions to Purification Challenges of Asymmetric Fc-Containing Bispecific Antibodies. BioPlan. 2024. In: 2024 21st Annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production.

- Roche.. Biotechnology: CrossMAb technology. Roche. Accessed September 12, 2024. https://www.roche.com/stories/crossmab-technology-in-research-technologies.

- evitria.. bYlok® bispecific pairing technology in bsAb production. Accessed September 12, 2024. https://www.evitria.com/bylok-technology/.

- Wan Y, Wang Y, Zhang T, Zhang S, Wang Y, Li Y.. Application of pH-salt dual gradient elution in purifying a WuXiBody-based bispecific antibody by MMC ImpRes mixed-mode chromatography. Protein Expression and Purification. 2021; 181:105822. doi:10.1016/j.pep.2021.105822

- Posted by Linda Carter